—Andreas Forer:

Professor Kortum, it’s a pleasure to speak with you about your recent white paper, The Future of Packaging in 2030 – An Empirical Analysis of Decision Makers on the Trend Toward Paperization. Since HEIDELBERG contributed to the study, we’re keen to understand its findings. Let’s start with the basics: What exactly does paperization mean in today's packaging landscape?

—Prof. Dr. Carsten Kortum:

Thank you, Mr. Forer. At its core, paperization is the shift from plastic to paper- and fiber-based packaging. It’s not just a trend, it’s a systemic change driven by rising environmental awareness and strong regulatory pressure. Consumers increasingly demand packaging that’s recyclable, renewable, and climate-friendly. In our study, nearly half of respondents reported buying fewer plastic-packaged goods, and over a third chose more sustainable alternatives.

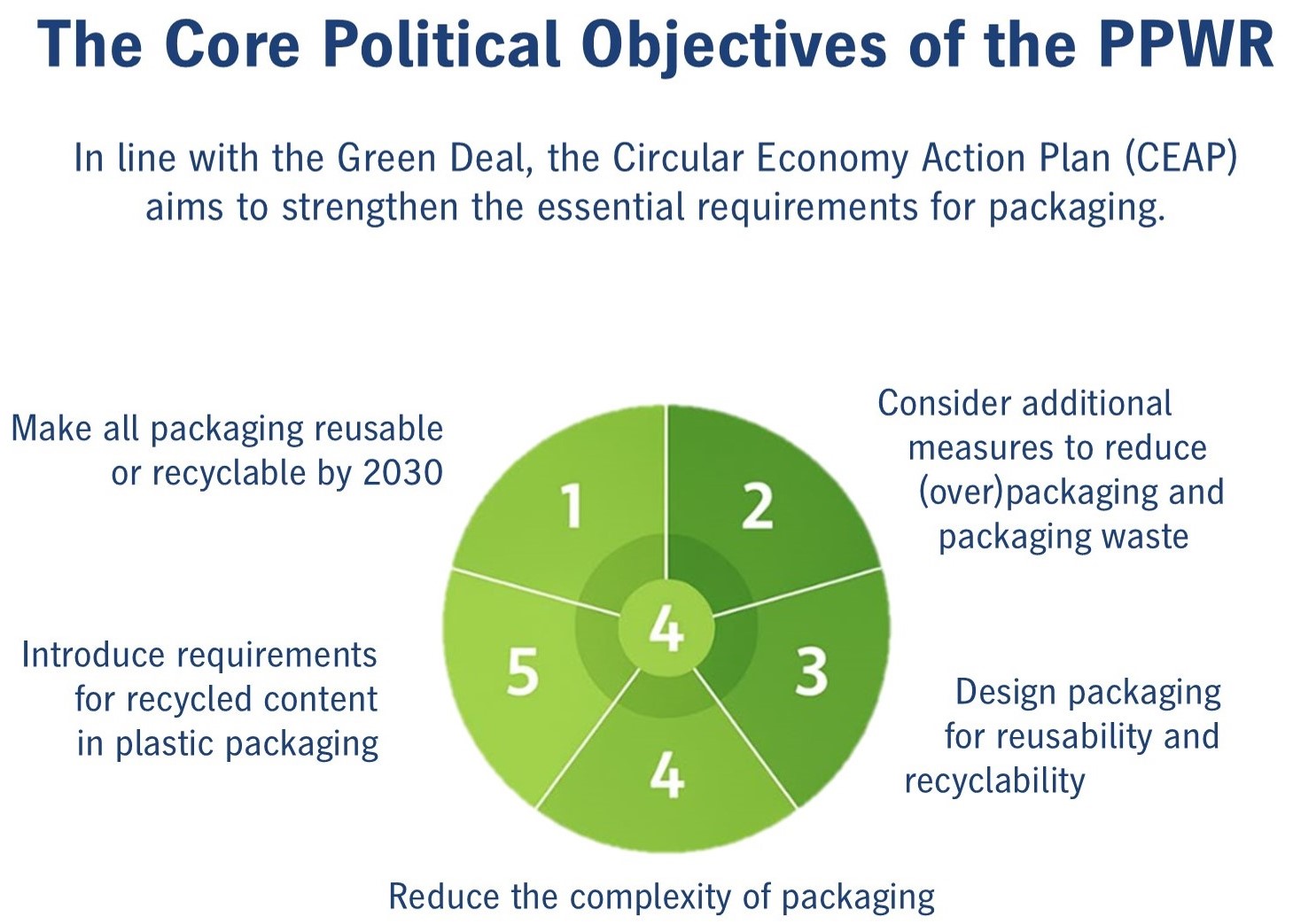

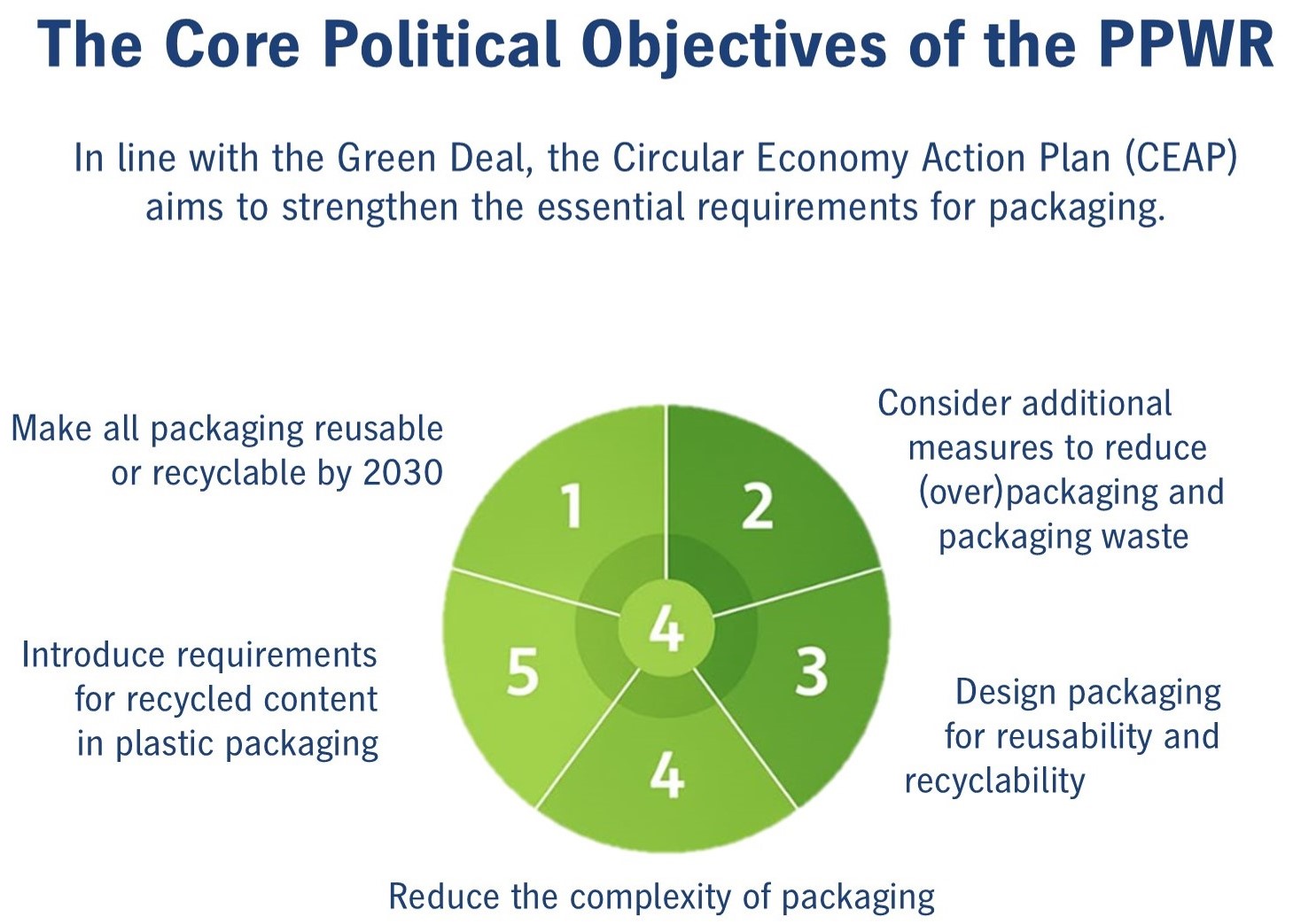

Equally important is the EU’s new Packaging and Packaging Waste Regulation (PPWR), which sets ambitious sustainability targets for 2030, banning certain single-use formats, mandating recycled content, and pushing for circularity. In retail and sourcing, I’ve seen how quickly regulation can shift market behavior. Packaging is no exception.

—Andreas Forer:

That aligns closely with what we see in the industry. Based on your interviews, what do companies see as the main benefits of paper-based packaging?

—Prof. Dr. Carsten Kortum:

Several, actually. First, sustainability: paper is seen as renewable and easier to recycle. Existing recycling systems for paper are robust and familiar. Second, consumer perception: paper signals environmental responsibility, which strongly influences buying behavior. Third, ease of disposal: unlike composite plastics, paper is intuitive to sort. And finally, versatility: paper can replace many plastic formats, particularly in transport and machine packaging, and it allows for high-impact printing and customization.

—Andreas Forer:

But the shift isn’t without challenges. What are the biggest hurdles when moving to paper-based packaging?

—Prof. Dr. Carsten Kortum:

Absolutely, there are real limitations. Technically, paper lacks the barrier properties needed for moisture, oxygen, or grease-sensitive products - think cheese, cosmetics, or electronics. Hybrid solutions or functional coatings are often required, which complicates recycling. Also, most packaging lines are optimized for plastic, making a switch costly and complex.

Economically, paper packaging tends to be more expensive, both in raw materials and in the required machinery upgrades. And while consumers want sustainability, they’re not always willing to pay for it, creating a tension for brands.

On the recycling side, coated papers can undermine recyclability if not designed for repulpability. Plus, many consumers remain confused about proper disposal, which affects actual recycling rates.

—Andreas Forer:

From our perspective at HEIDELBERG, several building blocks are essential to make paperization industrially viable and thus achieve the cost targets.

Important progress is being made in “design for recycling” with barrier coatings:

We are working with Solenis to optimize this process.

—Prof. Dr. Carsten Kortum:

That's right: these building blocks are essential for making paperization industrially scalable.

—Andreas Forer:

Let’s go back to regulation. What kind of impact is the PPWR having in practice?

—Prof. Dr. Carsten Kortum:

The PPWR is creating significant pressure for change, but with some friction. There’s a clear lack of operational clarity. Businesses are asking for:

Because national regulations still vary, international companies often run multiple packaging systems in parallel, which is inefficient and discourages investment. Many are waiting for final clarity before committing.

—Andreas Forer:

Looking ahead to 2030, how do you see the role of paper-based packaging evolving?

—Prof. Dr. Carsten Kortum:

For simple applications, paper with barrier coatings is likely to become the standard. There is particular potential for substitution in dry products, hygiene articles, and non-food items. Hybrid solutions will remain necessary for more demanding products. Plastics in mono-composites will also be used for the most stringent food safety requirements. The future lies in striking the right balance between sustainability, cost, and functionality.

Ultimately, the transition to sustainable packaging will only succeed if all players along the value chain work together – from substrate and consumable manufacturers to machine builders, brands, and retailers. The will is there. Now we need a reliable framework for implementation.

—Andreas Forer:

Thank you, Professor Kortum. This exchange underlines both the enormous potential and the real complexity of the transformation. It’s clear that technology, regulation, and cross-industry collaboration must go hand in hand.

—Prof. Dr. Carsten Kortum:

Agreed, Mr. Forer. I look forward to seeing these ideas turn into action, on shop floors, in design studios, and across the supply chain.

One goal, one solution: In partnership with Solenis, HEIDELBERG is pioneering eco-friendly paper packaging by combining advanced barrier coatings with cutting-edge flexo printing. A game-changer for cost-effective, sustainable packaging — especially in the food sector.