Buckle plates are the hearts of your folding machine. We demand a great deal of our buckle plates to ensure that you can achieve the best quality in your folding production. You will find the suitable solution for any requirement in our offer – from manual buckle plates with swing deflector over motor-driven combination buckle plates up to gate fold buckle plates.

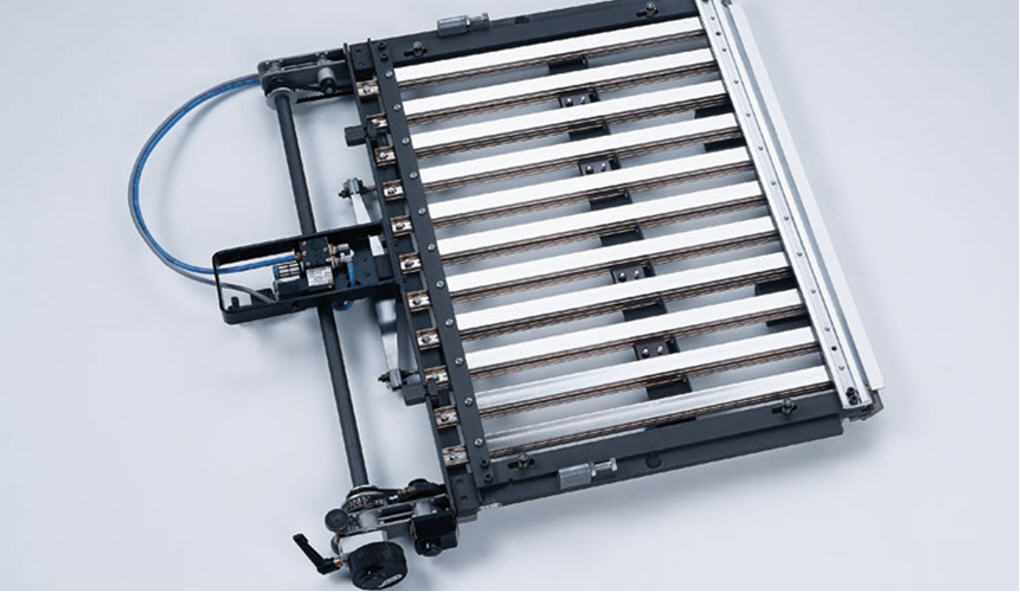

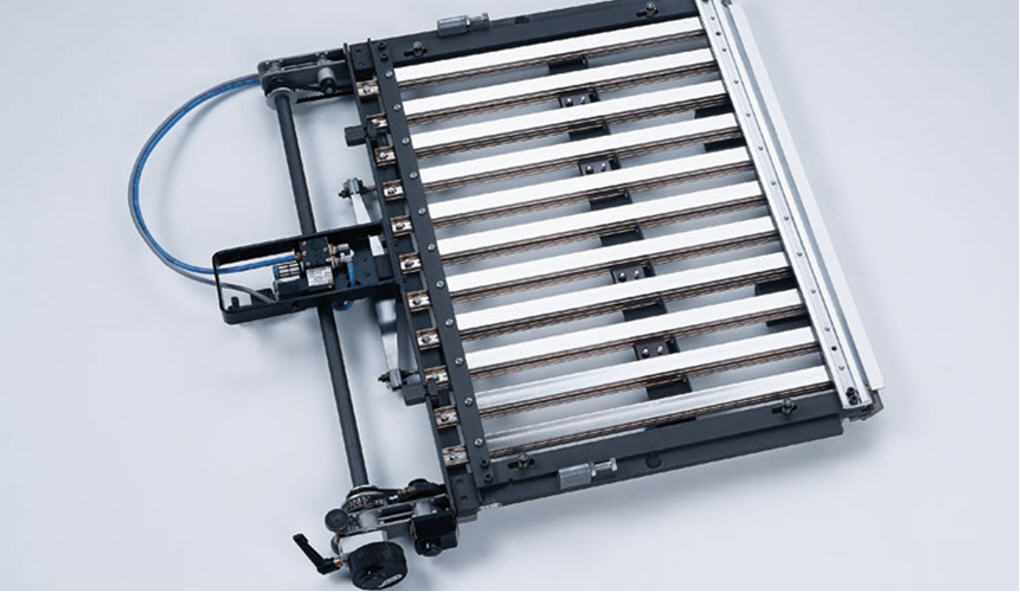

Buckle plates with swing deflector in manual machine configurations can be used flexibly as sheet deflector or buckle plate. The continuous sheet deflector profile ensures exact sheet guidance and can be swung without using any tools. The position and the angle of the sheet stop are precisely adjusted via a handwheel. If you use the buckle plate as sheet deflector, the sheet stop as well as the fine adjustments can remain in their positions.

Manual combination buckle plates make the operation of folding machines a lot easier. Change from sheet deflector to buckle plate function without taking the buckle plate out of the machine. You do not only save setup time but also avoid a damaging by storage outside the folding machine and moreover you reduce the physical stress for the operator. During the production you can make fine adjustments in the buckle space like clearance, pre-tension and position of the lower sheet infeed profile.

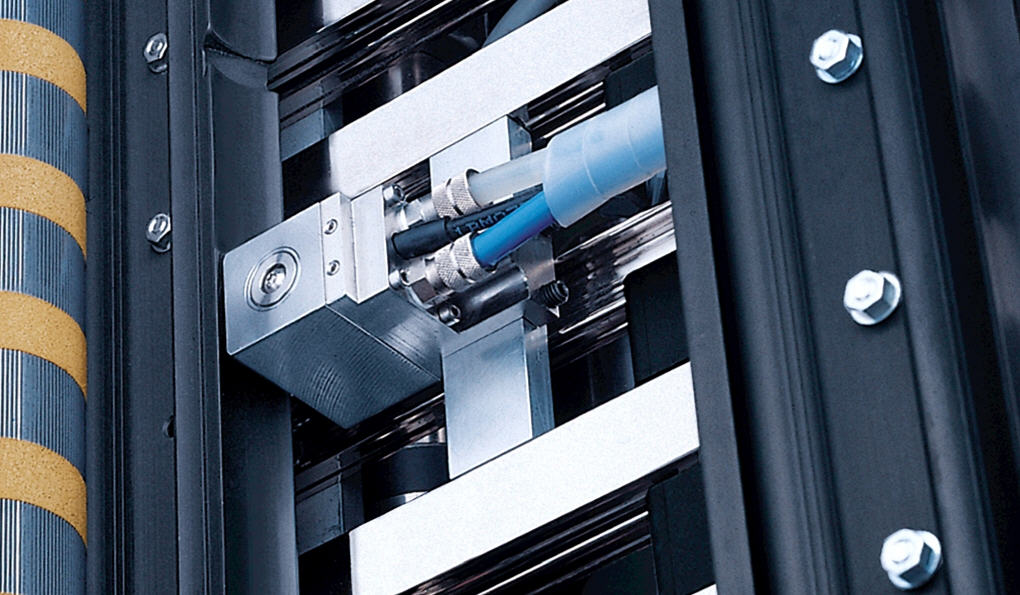

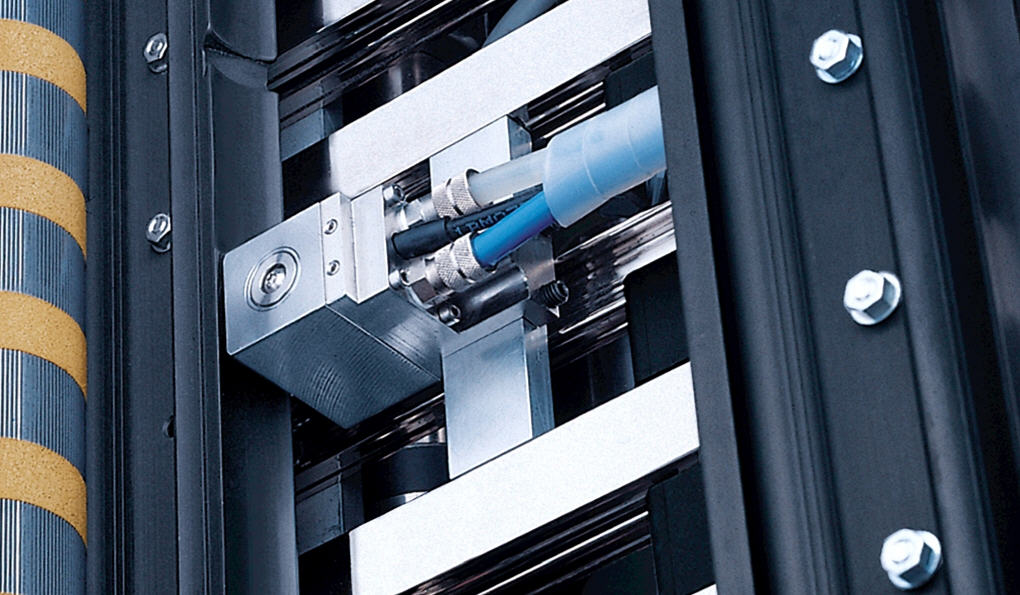

The motor-driven combination buckle plates of the automated Stahlfolder folding machines allow for a precise positioning of the sheet stop without manual intervention of the operator. The unique technology of two spindle drives of the motor-driven combination buckle plates of the Stahlfolder TH/KH and TX folders allows even motor-driven angle and deflector corrections besides parallel movement of the sheet stop – with an accuracy of 0.1 millimeters. Moreover the motor-driven combination buckle plates in comfort version feature a continuous sheet stop and a continuous sheet infeed profile. While the motor-driven combination buckle plate of the Stahlfolder TH/KH and TX folders also allow for settings in the buckle space like clearance, pre-tension and position of the sheet infeed profile during production, the motor-driven combination buckle plates of the Stahlfolder BH/CH folding machines are characterized by a strong belt drive with a reduced investment volume. With both versions of the motor-driven combination buckle plates the sheet stop is driven to its initial position when adjusting a new job, which corrects mis-adjustments and angle adjustments. You can store all adjustments and quickly retrieve them in case of repeat orders. This helps you to achieve top fold quality even for challenging papers.

The small format buckle plate in working width 56 was developed based on the motor-driven combination buckle plate and is especially suitable for the production of miniature foldings. The smaller partition of the infeed profile ensures safe sheet guidance with two supporting points even with small products. With this buckle plate you can produce folded products with a minimum fold length down to 35 millimeters.

The double-gatefold is a popular folding method amongst graphic designers. However, with the equipment available so far much experience and skill was needed on the part of the operator in order to deliver the job on time and in the high quality required.

The pneumatic gatefold buckle plate is digitally controlled. The pneumatics open and close the deflector. The ACC 2.4 digital control module precisely controls the timing independently of the folding speed. Precise control of the deflector profile lets flaps be as close together as 0.5 to 1.0 millimeter (0.02 to 0.04 inch), depending on the paper thickness. High cycling rates (up to 15,000 cycles per hour) can be achieved effortlessly, even during continuous operation.

In the motor-driven gatefold buckle plate, the paper stop is positioned quickly, securely and precisely by a motorized spindle. The accuracy of the positioning can be fine-tuned to within 0.1 millimeter (0.004 inch). Presetting can also be performed using the fold catalog. Repeat jobs can be easily stored.

Our versatile range of creasing, perforating and cutting tools helps you to enlarge the quality, the application field and the productivity of your fold production. Creasing and perforating tools prepare the fold products for further process steps and increase the quality of your products. Cutting tools help you to trim the folded products to their final format or to separate several ups. Thus you produce final products on your folder and increase your output.

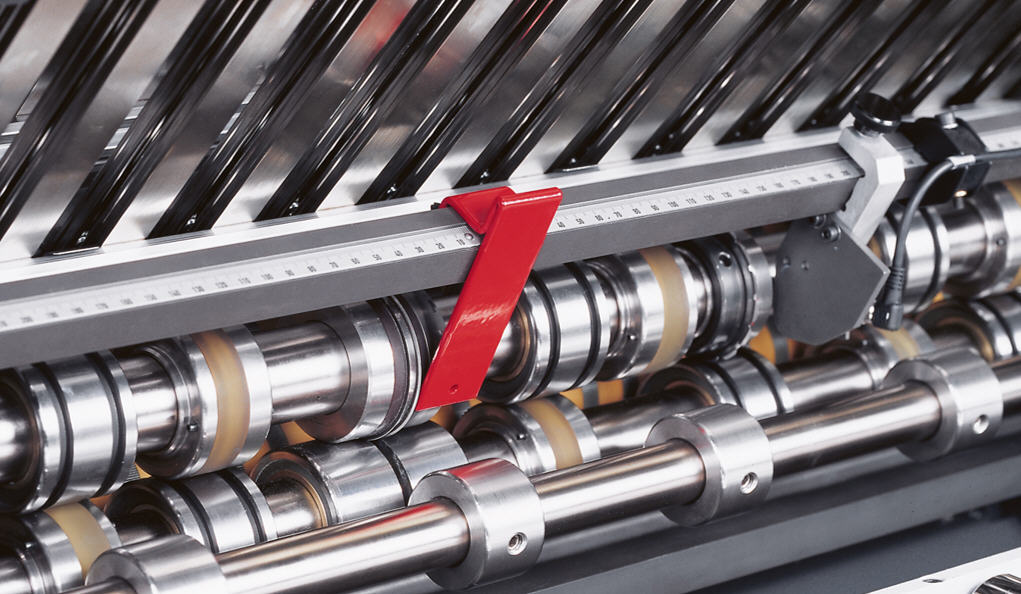

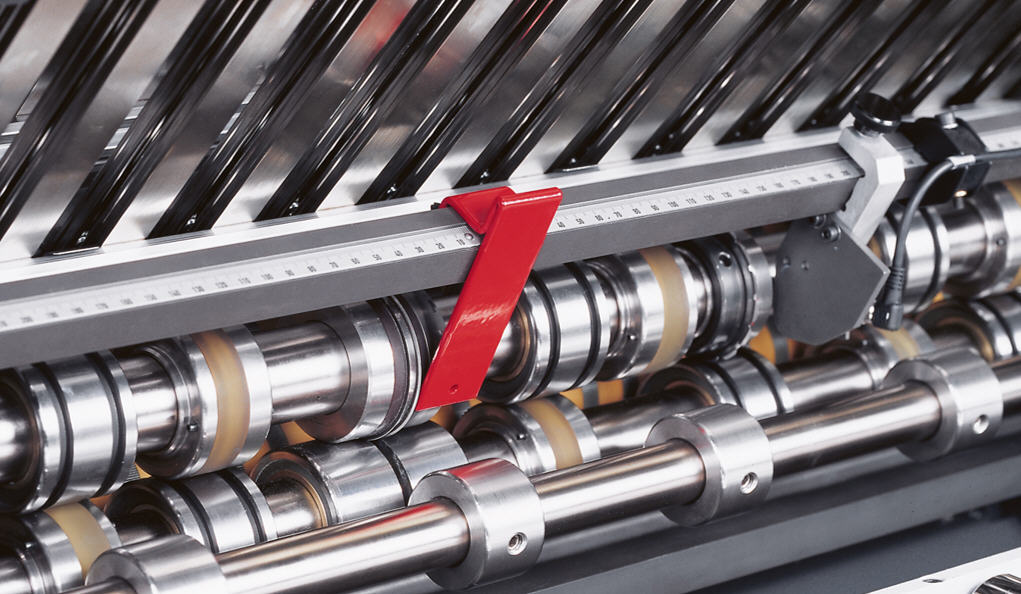

You can use scoring tools on the front-mounted or rear-mounted slitter shafts of your folding machine. This processing makes the following cross-folding easier and increases the fold quality, regardless of the applied fold principle – buckle plate or knife fold. Scoring devices against PU-rings achieve a higher quality and can be setup quicker than scoring devices against steel. For especially high quality demands when processing high grammages, we offer you the special device Tri-Creaser Fast-Fit. This way you do not only avoid a cracking of the paper coating and paper fiber but you can also score inline in the folder thus saving an additional processstep on the printing cylinder.

Our perforating tools are available with various slot lengths and gutter lengths. This enables you to adjust the tool perfectly to the paper quality and the fold type of your job. Slot perforations reduce the material tension and let the air escape from the signature, thus avoiding creases. Slot perforating tools with a large number of teeth are suitable to produce tear-off perforations. They are used for instance to produce calendars or mailings and help the end user to detach individual sections. Punch perforations make the production of versatile cross-folds a lot easier. Due to the wide punch holes the entrapped air can escape from the signature. Moreover it is often possible to finish punch perforated sheets in the perfect binder without milling.

Cutting knives allow you to do parting cuts, edge trimmings and strip trimmings. With a parting cut you separate various ups easily. For the processing of thicker products we offer you double circular knives. They work like a pair of scissors: cutting knife against cutting knife. Edge trimmings allow you to trim the signature to a final format with a head and tail trim. They are used for instance when producing fold-glued brochures. Strip trimming devices work with two parallel knives. They allow you to cut out strips from multiple-ups, removing the paper strip reliably from the working area.

Gluing attachments allow you to expand your product range with attractive final products. Produce inline in single pass-through 16-page brochures, envelopes, photo bags and much more. Gluing devices also improve the handling of intermediate products. With auxiliary gluing, envelopes and folded sheets can be processed easily on saddle stitchers or perfect binders.

Cold Gluing

Cold gluing attachments consist of a glue tank and contactless application heads. This increases the process reliability. Size and spacing of the dots are controlled by the control unit. Even intermittent applications on one sheet are possible. Cold gluing is used for products such as photo bags.

Hot Melt

Hot melt systems consisting of melting tank, heated hose and nozzle or surface coating systems are mostly used in mailing machines. Possible applications are sealings of direct mailings and re-moistening coatings.

Inplate

Inplate attachments are used as auxiliary gluing applications. They allow you to stick sheet flaps with a few spots of glue and can be removed easily by trimming. Given a compact glue valve, it is set directly on the buckle plate. Clearances, e.g. in the folding rollers, are not necessary.

With the digital control module ACC 2.4, you can control gate fold buckle plates, gluing devices and EAP heads for timed perforation exactly. The integration of these operations in the folding process increases the value of your folding production.

The digital control module ACC 2.4 is clearly arranged an with its graphical symbols easy to handle. So you can control up to two gate fold buckle plates, glue valves or EAP-heads accurately. Your advantage: The triggering is path-dependent and working independent of the machine speed. Therefore, following optimizations on the machine’s speed don’t constrain you to re-adjust the settings of the control unit.

For example, the production of double gate folds is made much easier. In short set-up time and in combination with the gate fold buckle plate FFP the flaps can be as close together as 0.5 to 1 mm at 15,000 cycles/h. Not at least because of the reduced investment costs compared to conventional control devices for a specific application, the control module ACC 2.4 assures full flexibility for the production of demanding folding applications.