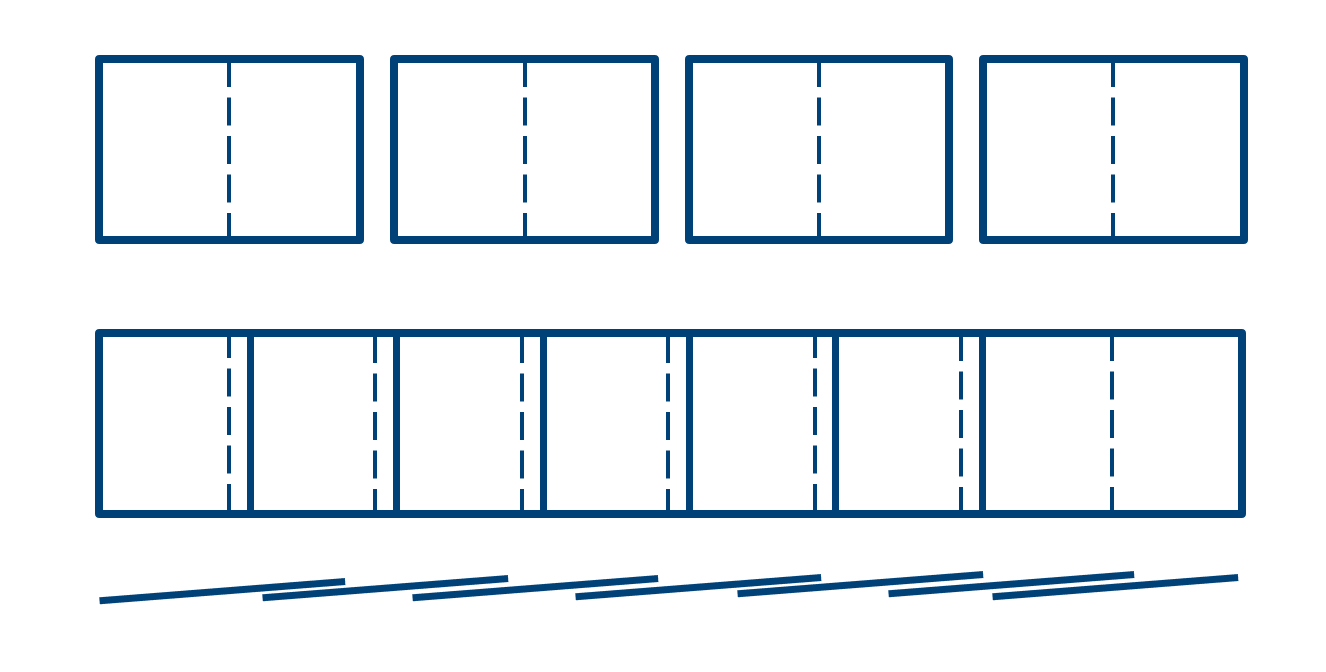

The unique shingled folding technology of the Stahlfolder machines not only reduces sheet spacing, but ensures that there is no gap between sheets. This makes it possible to maximize the productivity of your machines while maintaining quality and process reliability.

By shingling the sheets, more sheets per time unit can be folded - without increasing the machine speed. This allows for increased output without any quality loss.

Calculation based on a 16-page DIN A4, open format 63 x 88 cm

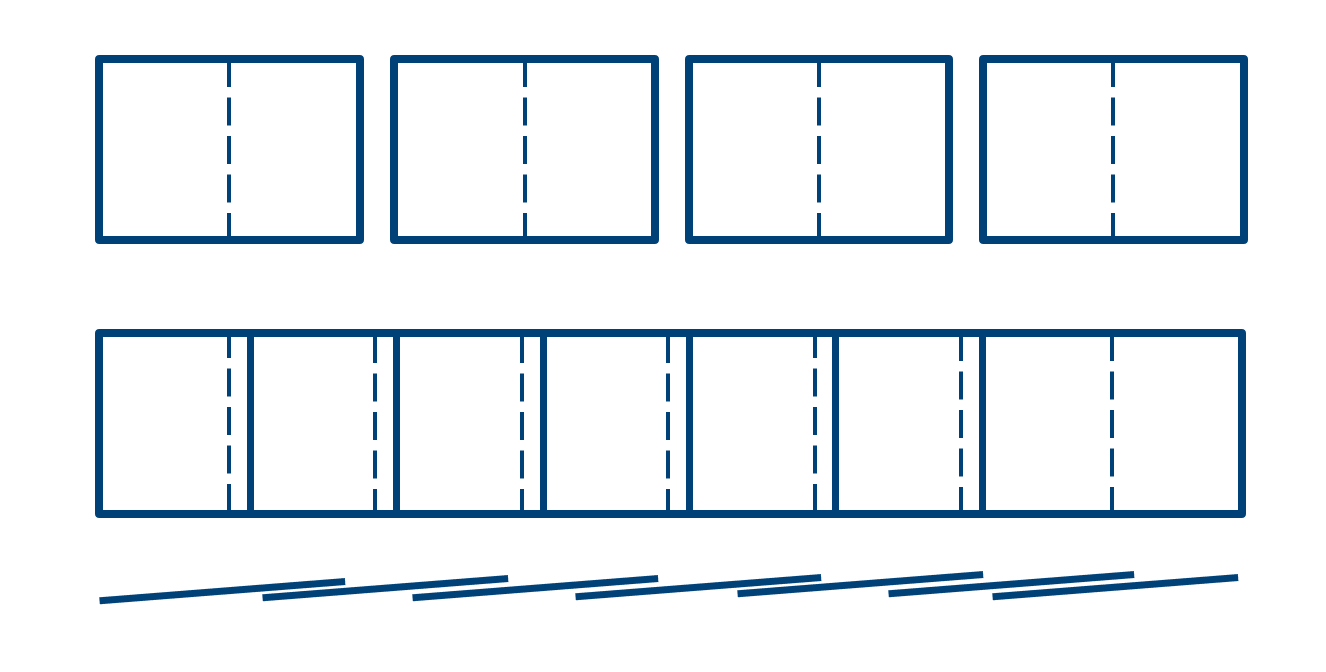

The infeed length for conventional folding with 4 cm sheet spacing is 92 cm. This means approximately one sheet per meter. At a press speed of 135 m/min, this makes around 8,800 sheets/hour.

There are two approaches to increasing the gross output of this job to 16,000 sheets per hour:

Have shingled folding elevate your business with our bundled package of Stahlfolder TH/KH 82-P+ Flex system + P-Stacker.

“We already had an ace up our sleeve with the TH 82-P high-performance folding machine. (...)Thanks to the P-Stacker, we’ve increased our signature output by over 20 percent , and our productivity and capacity overall.”

Günter Kunesch, Managing Director, Koller und Kunesch