With its completely redesigned platform, CutStar stands for high automation, simple handling and ease of maintenance. This makes it highly productive, particularly when using foils and thin materials.

As a reel sheeter, the CutStar is the ideal complement for processing thin label papers or films at high speeds of up to 21,000 sheets per hour. In its fourth generation, the CutStar has a completely new, maintenance-friendly design that also reduces makeready times. Its high level of automation, combined with integration into the Prinect workflow, can reduce makeready times by up to 50 percent. Extensive preset values for different substrates now ensure significantly accelerated makeready times when changing materials. Manual settings such as the format length setting are no longer required.

Increasing customer requirements, particularly for processing thin substrates such as label papers and in-mold foils, were the catalyst for developing a new CutStar - the focus was on higher print speeds, more stable sheet travel, greater automation, easier handling, and greater ease of maintenance. Integration with the Push to Stop and Intellistart functions of the press makes the CutStar unique. The press and CutStar communicate continuously with each other.

This means that important information about the CutStar can be displayed directly to the operator on the machine's wallscreen. During job changes, the CutStar can be disconnected from the feeder at the touch of a button. This makes it easy to switch production from processing reel stock to sheets. The next job can then be printed directly from the pile instead of from the roll.

With the 4th generation CutStar, production speed for thin substrates has been increased by 30% and the range of applications for particularly thin materials (foils from 40µm and paper from 30g/m²) has been significantly expanded.

Efficient production of labels thanks to:

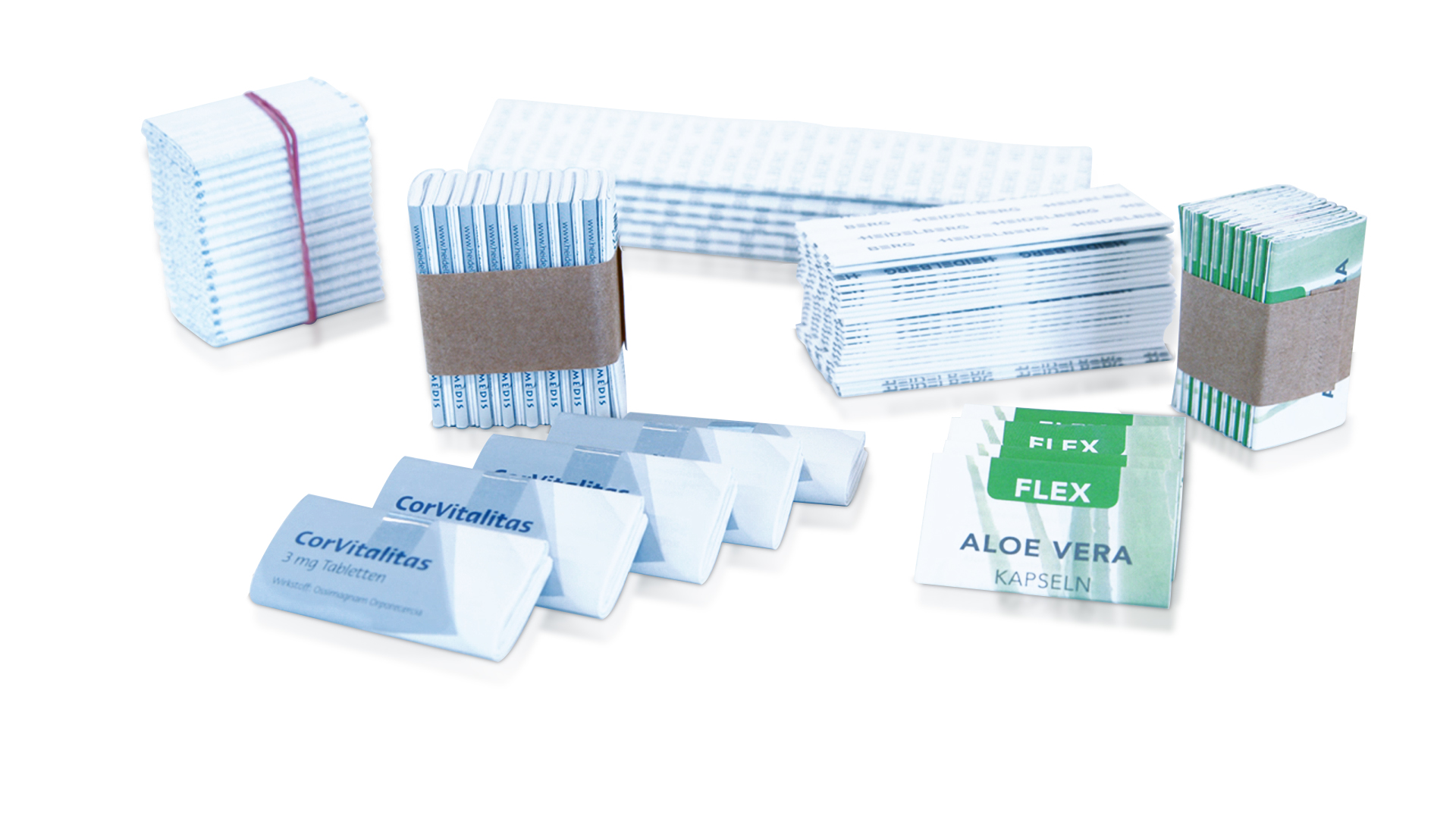

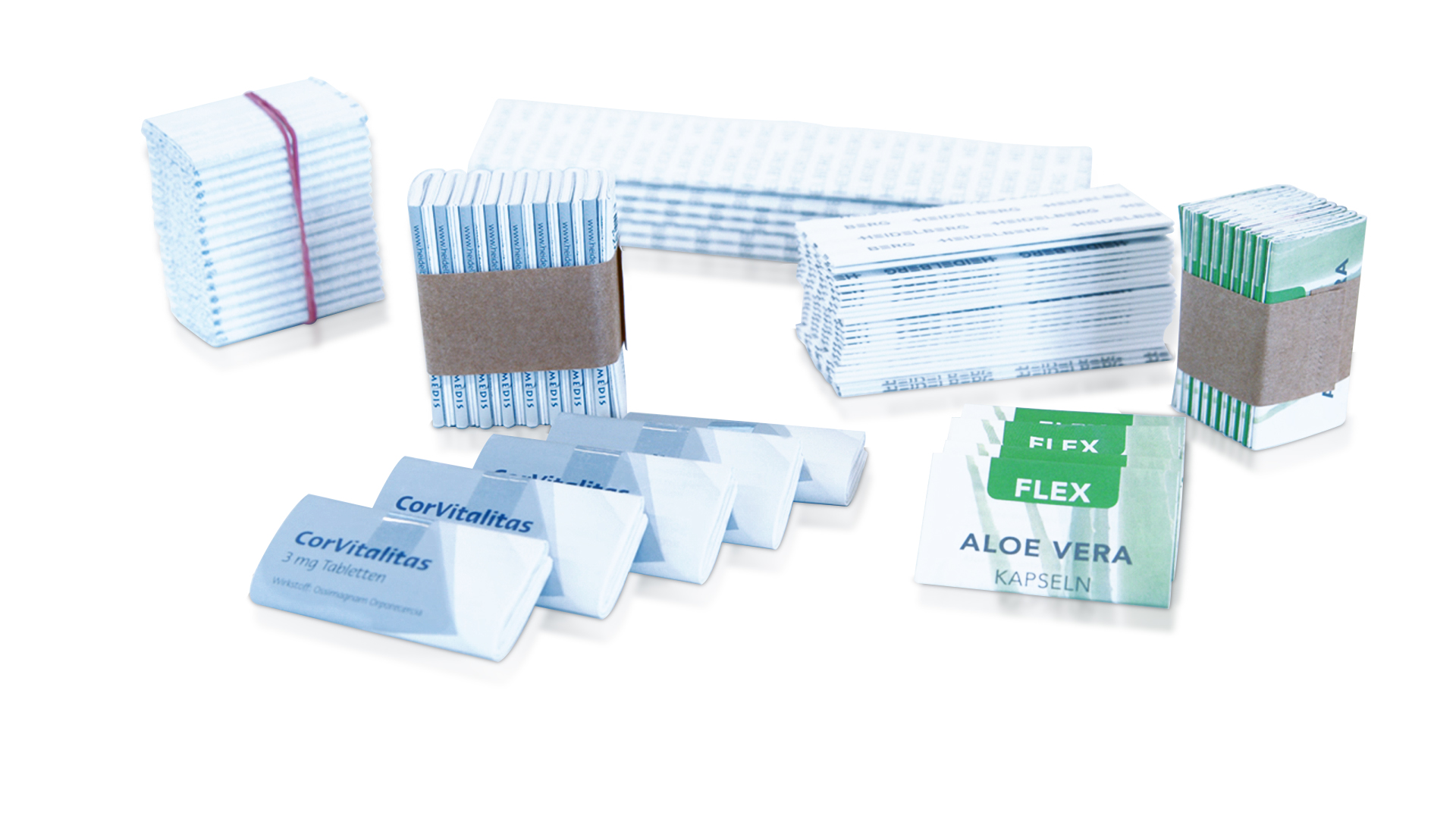

Package inserts are an important part of any pharmaceutical or cosmetic product packaging. However, they are also diverse and demanding to produce. The increasing information content goes hand in hand with growing space requirements and therefore printing on the very thinnest of materials.

The 4th generation CutStar is an excellent solution to the special challenges posed by thin materials. Papers from 30g/m² can be processed without any problems.

Efficient production of package inserts thanks to:

High production speeds up to 21,000 sheets per hour with reduced number of pile changes and fewer wash-up cycles, increase net output. Waste reduction, the optimum format, and lower roll prices ensure cost-effective and competitive production. The flexible use of the 4th generation CutStar enables a wide range of jobs from particularly thin materials such as paper from 30 gsm up to cardboard up to 300 gsm and is economical - for both short and long runs.

Efficient production of commercial jobs thanks to: