The Speedmaster Operating System with intuitive touch control on the 24-inch multi-touchscreen turns the convenient control of the Speedmaster into an experience. Settings can be called up with a click, and the scalable operation can be flexibly adjusted in accordance with the requirement profile (Smart Setup).

Intuitive operator guidance, innovative gesture control, and integrated help functions in 27 languages eliminate lengthy searches. The Speedmaster Operating System delivers fast simple and navigated use of all your machine’s functionalities.

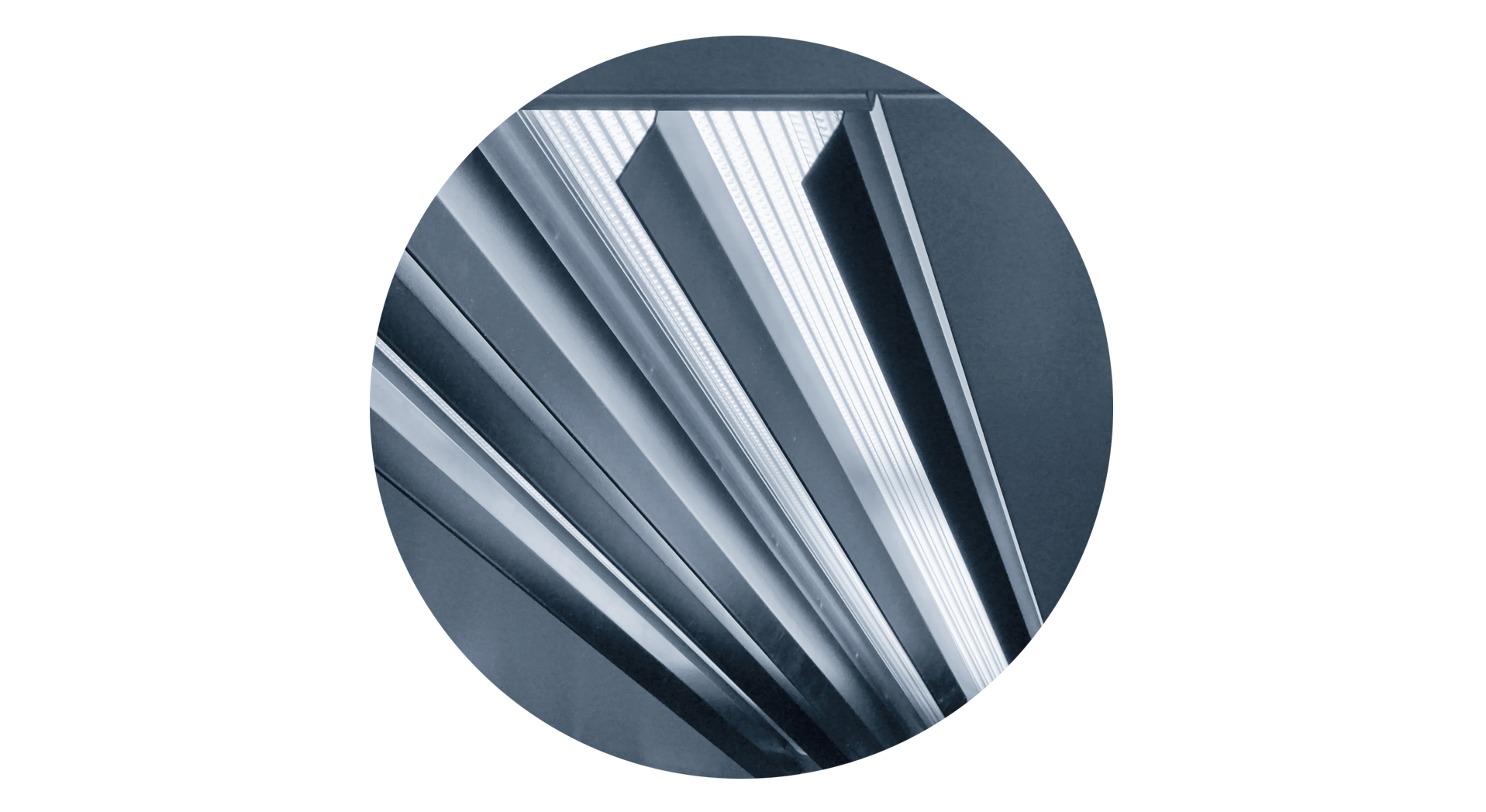

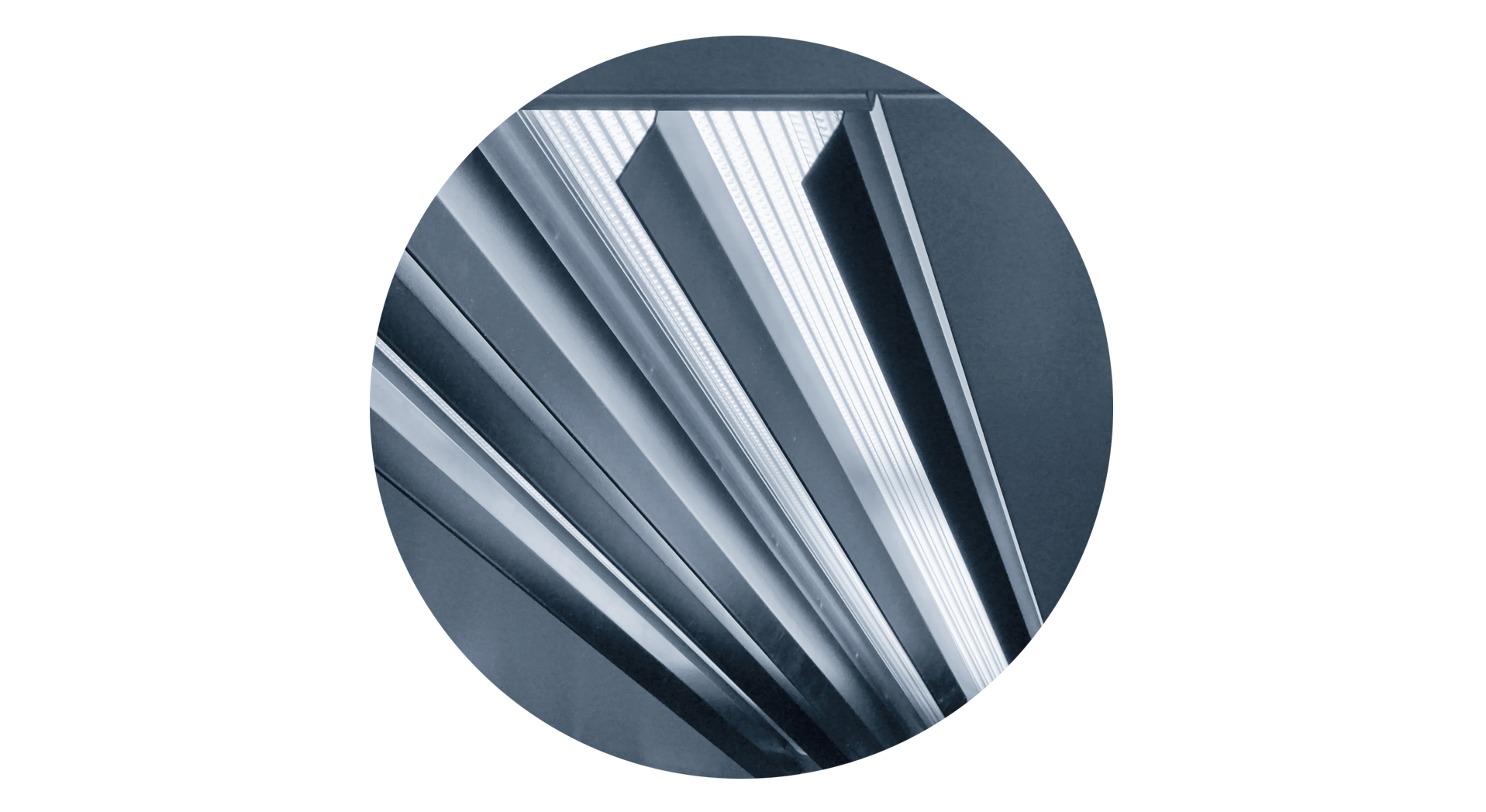

The integrated LED daylight lamp allows optimum illumination of the print sheets during matching. Prisms and Fresnel lenses produce a uniform but at the same time directional illumination that facilitates the detection of coating defects as well as problems in the screen. The operator is not dazzled, is never directly under the light source, and the Wallscreen in the background is without reflection, as is the print sheet.

The lamp is dimmable if required, as well as switchable between D50 and D65, making it suitable for other applications such as photography and textile patterns. Likewise, it is now easy to select D50 without and with UV content (M0 - M1). This makes it possible to match e.g., proofs according to FOGRA39 and FOGRA51 at the push of a button.

Navigated printing with Push to Stop

is possible on all Speedmaster machines.

Intellistart 3 defines all the steps required for the job change

without any operator intervention and provides maximum transparency across

all active and queued processes. Intelliguide simulates the time-optimized sequence live

and, if necessary, also includes the steps to be executed manually.

Productivity without interruptions with the fully automatic job changeover

from the last to the first good sheet and the start of production.

Note: Components are not always available for all models.