Zero defect deliveries – this is how the North American packaging specialist Utah Paperbox is winning over its discerning pharmaceutical and luxury goods customers. And steadily increasing its orders and reach in the process. This is because the Diana Eye 55 offline inspection system ensures that each folding carton fully meets the quality specifications.

One of the big strengths of Utah Paperbox (UPB) lies in what it does not do: ship defective folding cartons to customers. Quality assurance is the most important thing for the packaging specialist. After all, the family-run company based in Salt Lake City has enjoyed an excellent reputation in the market for four generations. It is one of the most diverse packaging printers in the USA and a go-to company for high-end customers from the consumer goods industry and recently from the pharmaceutical industry. “We do not rest on our laurels. Because we know that we have to reaffirm our image with every job,” says UPB President and CEO Steve Keyser. And if the quality is ever not perfect? “Then it’s about making sure that the defect does not reach the customer,” says Keyser. The Diana Eye 55 is a way of ensuring this.

For a year, the offline inspection system has ensured absolutely reliable quality control. “We are supplying more and more customers in an ever-growing catchment area in the West, Midwest, and East of the USA. We don’t want to get a complaint about a single job,” says UPB VP Operations Mike Salazar. He was therefore well and truly fascinated by the Diana Eye when he experienced it live for the first time at the last drupa. The system provides exactly what he was looking for: total quality control of the entire print image and all embellishments on each individual folding carton.

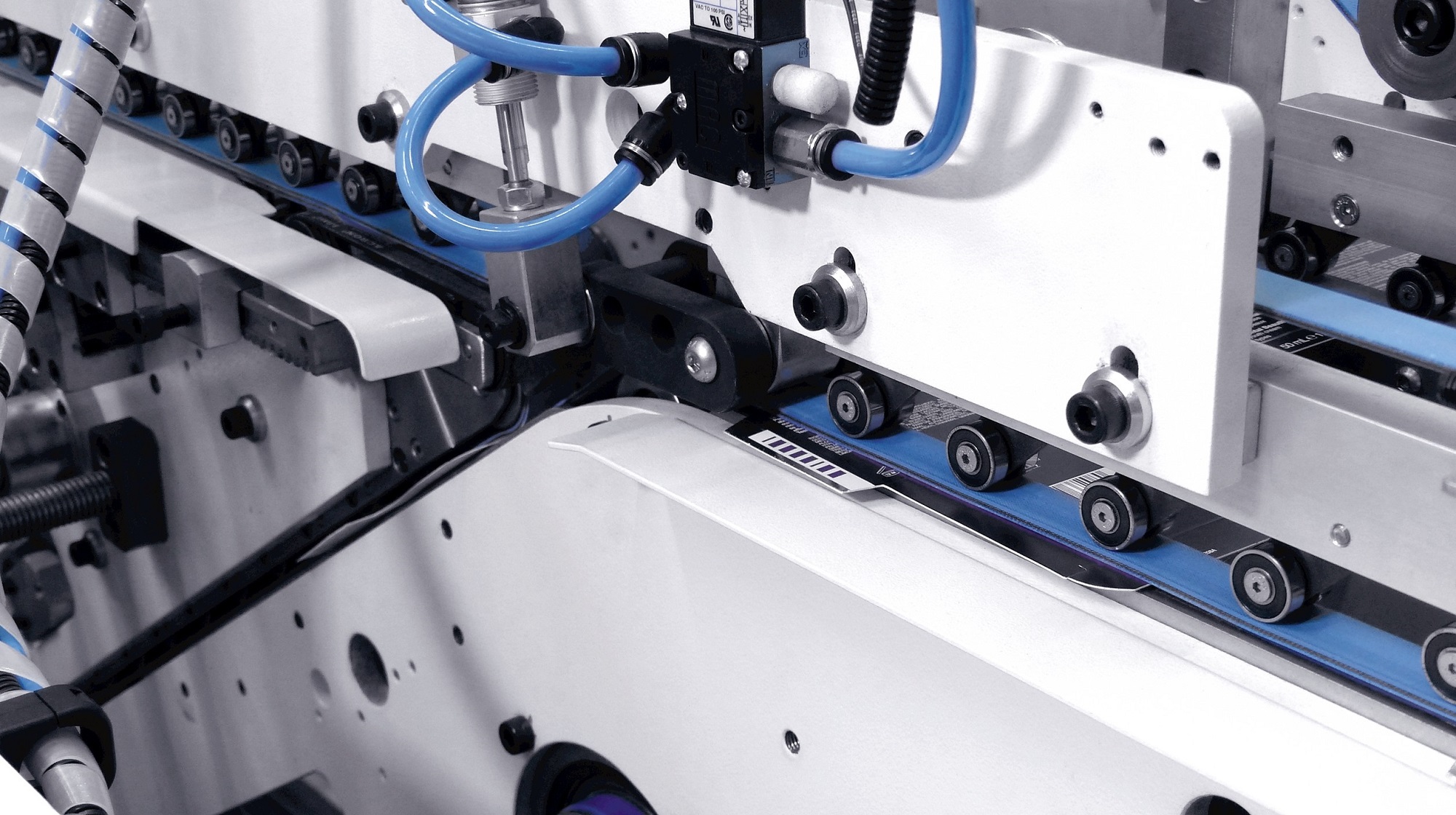

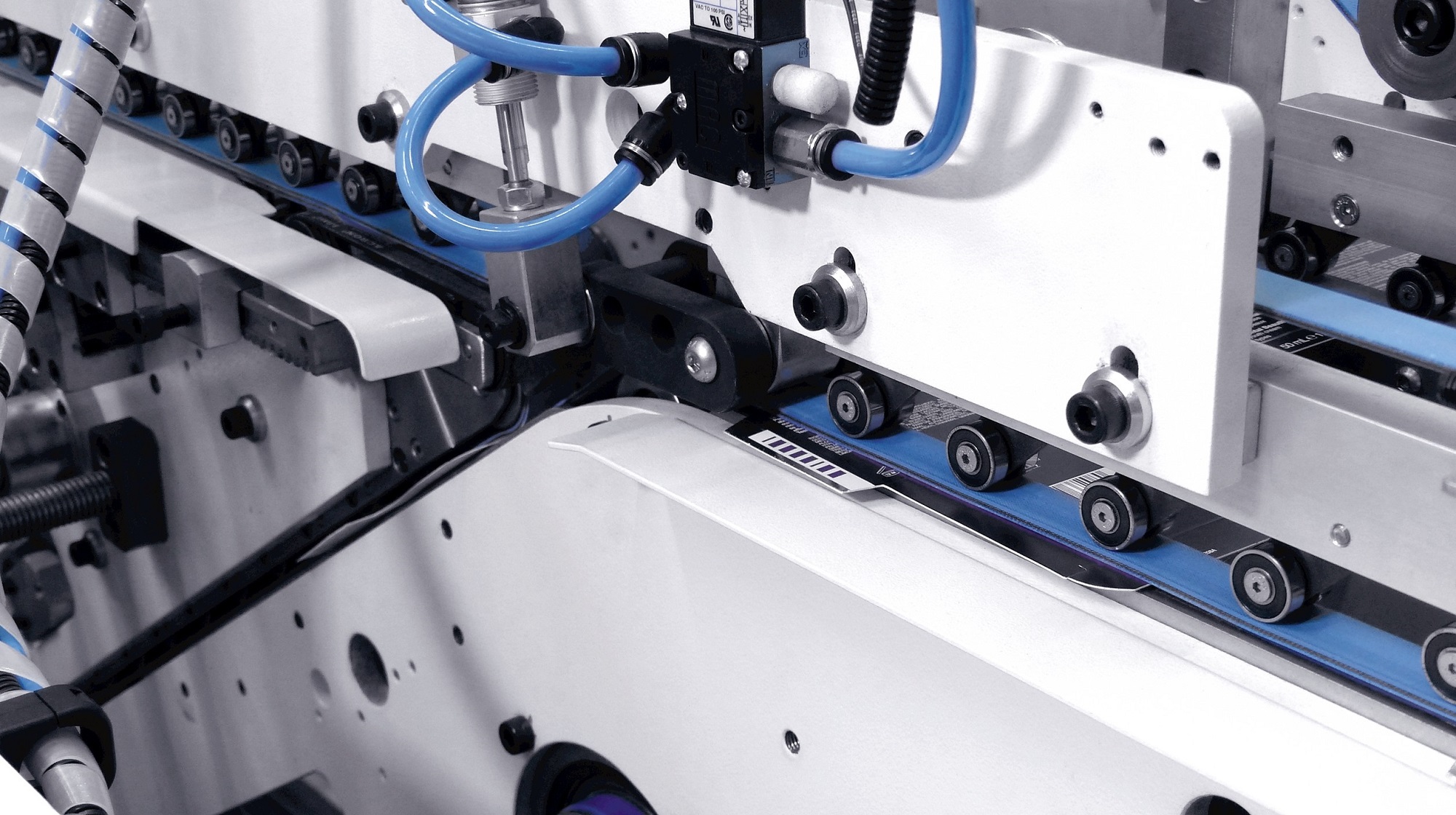

The Diana Eye 55 offline inspection system checks the details on the printed surface using up to four cameras

The Diana Eye 55 offline inspection system checks the details on the printed surface using up to four cameras

The Diana Eye does its work at a key strategic point in the production chain: it checks the blanks before they go to the gluers. And at speeds of between 50,000 and 120,000 units per hour. “If you make so much as a small scratch on a carton with a needle, the Diana Eye will find it and sort out the blank,” says Keyser. “For us it is the best and most cost-efficient solution.”

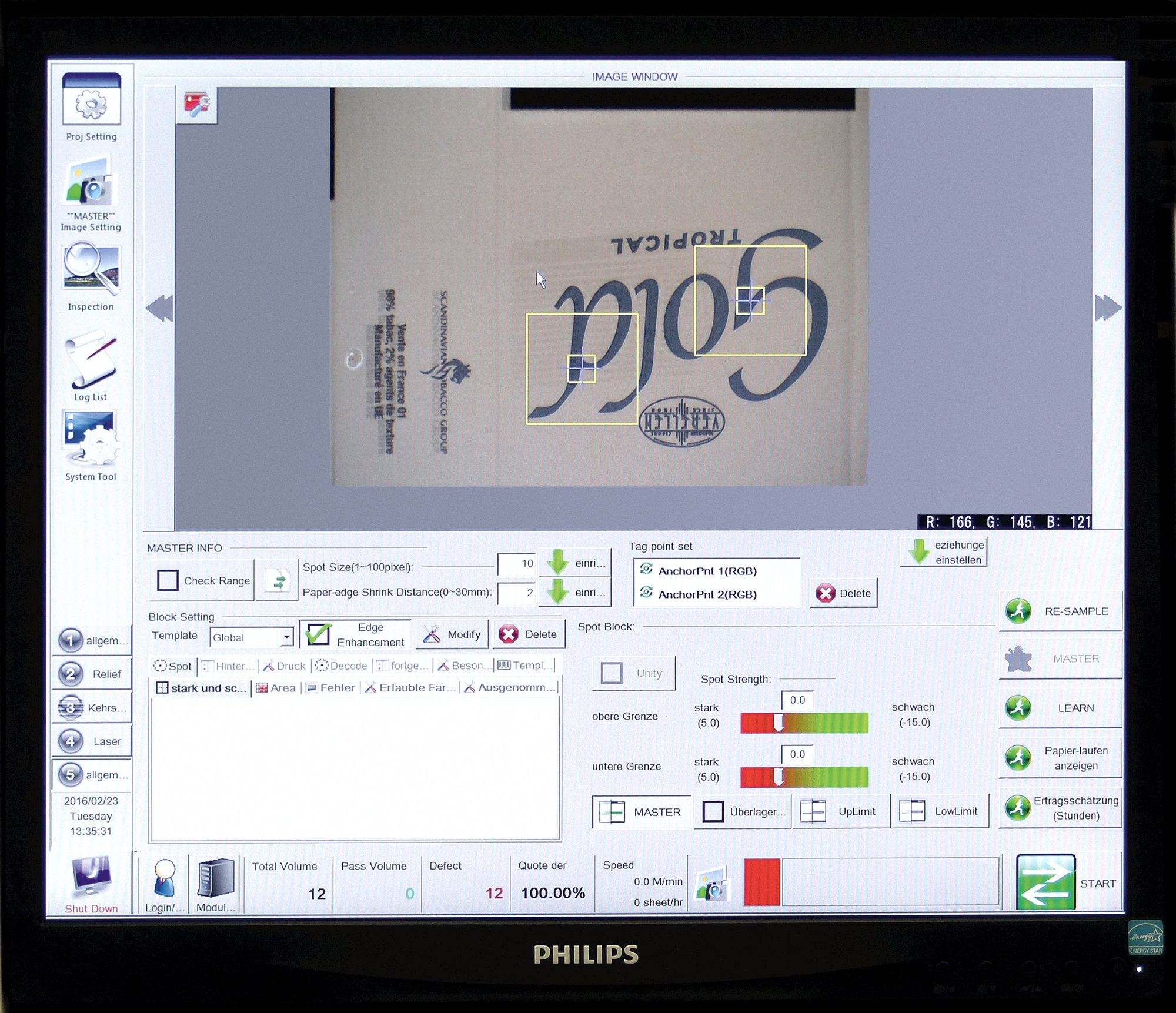

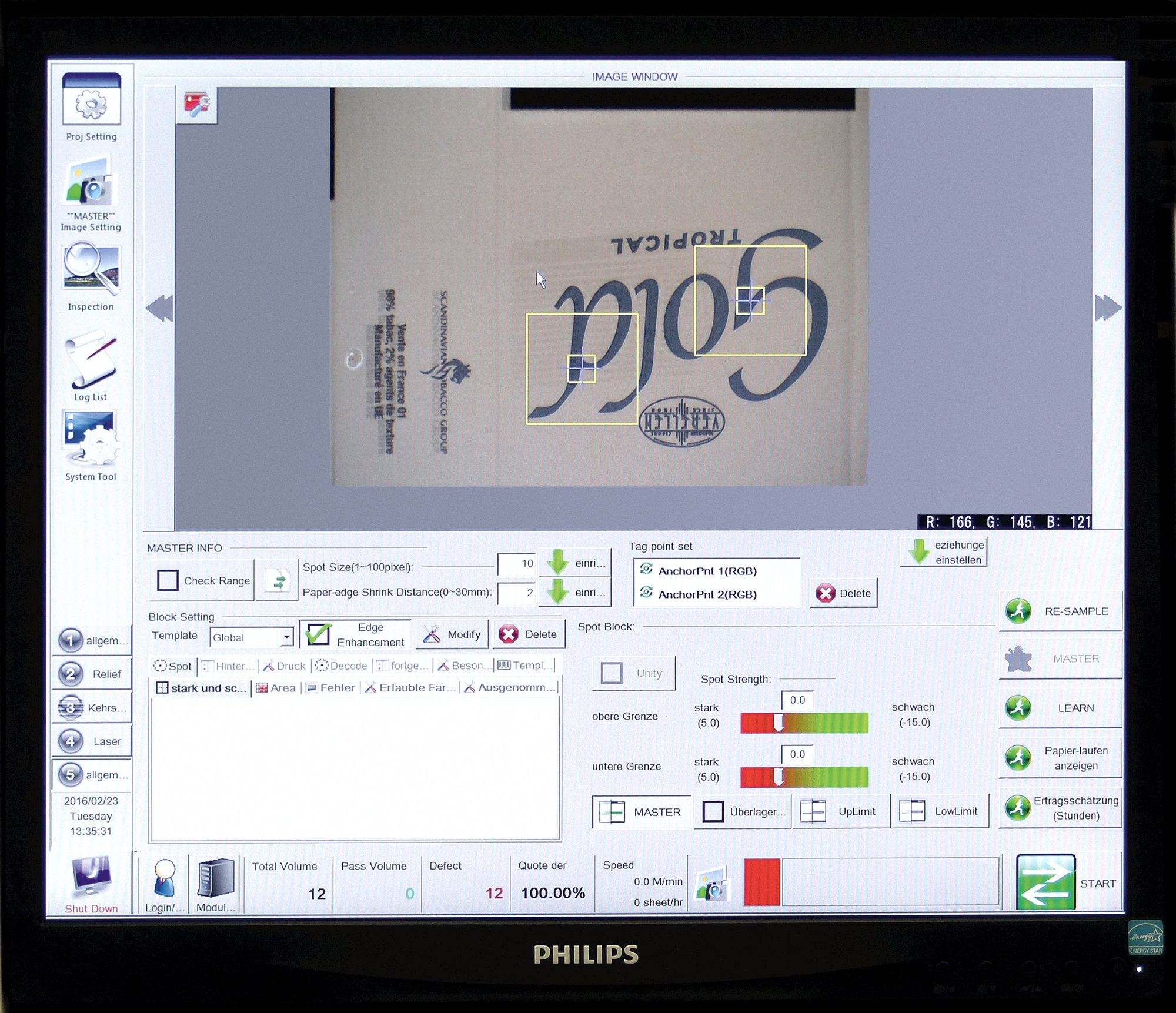

UPB is not able to perform a complete quality check on the respective postpress machine during the postpress stage. The integrated inspection systems reach their limits as soon as highly reflective substrates or high-quality finishings need to be checked. The Diana Eye fills precisely this gap. “The system’s capabilities are unbelievable. We can use it to check everything, regardless of the associated production step: print quality, color, gloss, coating effects, hot and cold foiling, metalized surfaces, windows, and even die-cutting operations. Up to now, we had to check a lot of things by hand. With the Diana Eye, we can now do this automatically. This speeds up our workflow and shortens the throughput times,” says Salazar. While production continues on the relevant machine, the system checks the blanks in question.

The Diana Eye checks the details on the printed surface using up to four cameras. It can also verify the backside of the carton using a further, optional camera. Blanks where the quality is not perfect will be rejected, without being damaged in the process. This reduces the waste, since the defective blanks are used to set up the gluers as well as the Diana Eye itself. “To determine the tolerance ranges for quality inspection, we check the blanks once again manually or with the system. We save the defined tolerance values in the Diana Eye for repeat jobs,” says Salazar. UPB inspects delicate layout elements that require a particularly thorough inspection using an extremely high-resolution camera.

Diana Eye ensures that each folding carton fully meets the quality specifications

The inspection system not only meets the high standards in high-end packaging printing, but also the strict regulations of the pharmaceutical industry and in medical technology. “The customers in those industries demand total quality control of their cartons. The Diana Eye for us is the entrance ticket to this market,” says Salazar. Added to this are further efficiency advantages in daily operations, for example for cold-foiled embellishments. The Diana Eye is a huge gain for one job in particular, as Salazar reports: “We print the job on a press in 100 x 140 cm format. We use a 127 cm wide stamp for embossing. That was always fiddly because of the register. Now we can ensure that the cartons are perfect and on top of that save a lot of time.” In addition, the Diana Eye also provides the printers with valuable information through its ability to detect even very fine ink mist on pure white cartons.

The name “Heidelberg” made the decision in favor of the Diana Eye an easy one. SystemService for technology and performance ensures that users get the most out of their machine and, if necessary, that a technician can quickly be on site. “Heidelberg stands behind the product and services the machine, which will therefore run stably for many years,” says Salazar with conviction. He is completely satisfied with the Diana Eye, which enables more business: “The system helps us to achieve much higher quality, and it does so at top speed. Some of our customers expect this level and demand total quality control of their folding cartons. Thanks to the Diana Eye, they can be sure that they will get it,” summarizes Salazar.

920 S 700 W, Salt Lake City

UT 84104, USA

Tel +1 801-363-0093

upbslc.com